-

For dentist

- Dental loupes with light

- ADAE Dental Loupes Expert Consultation

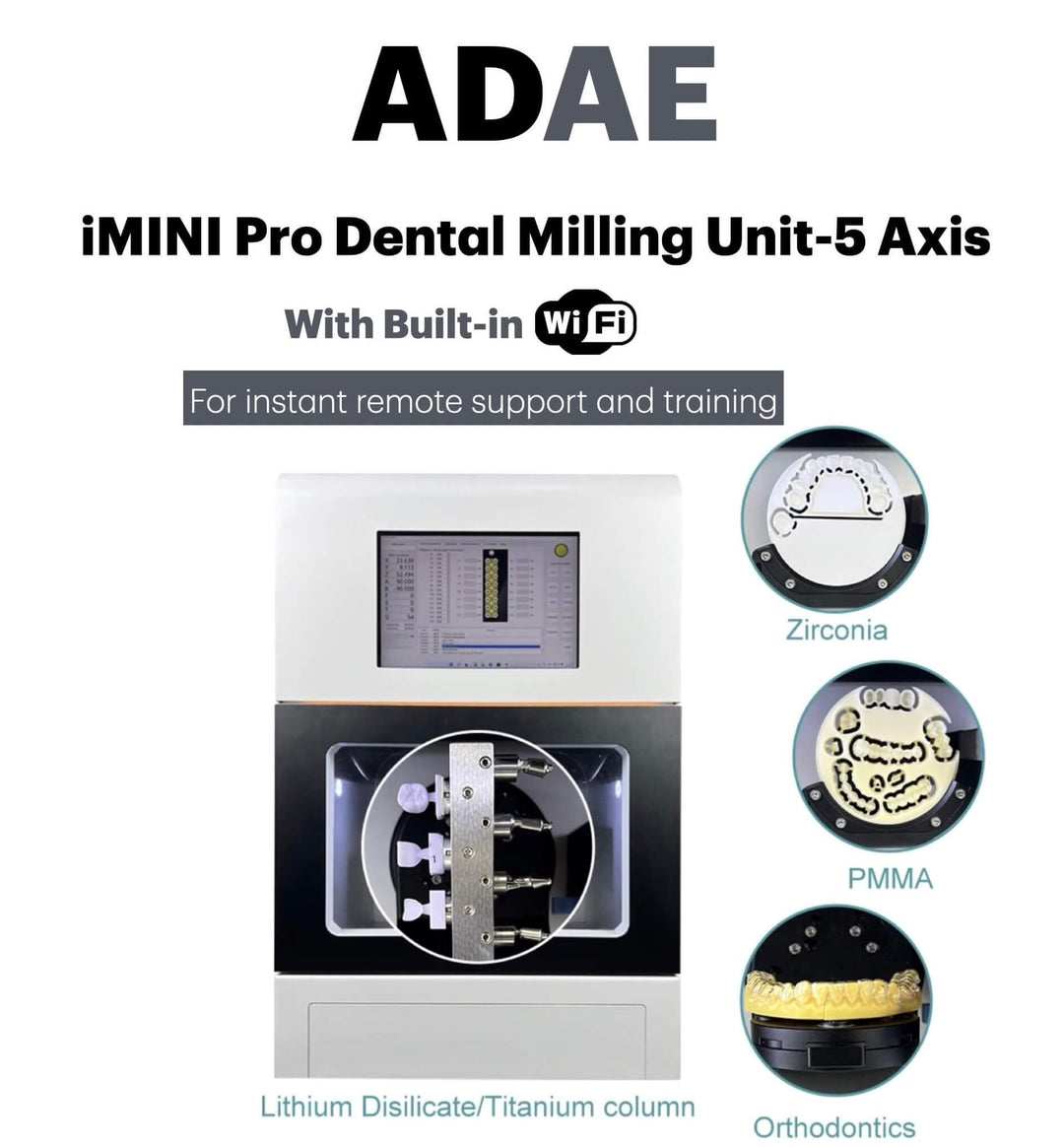

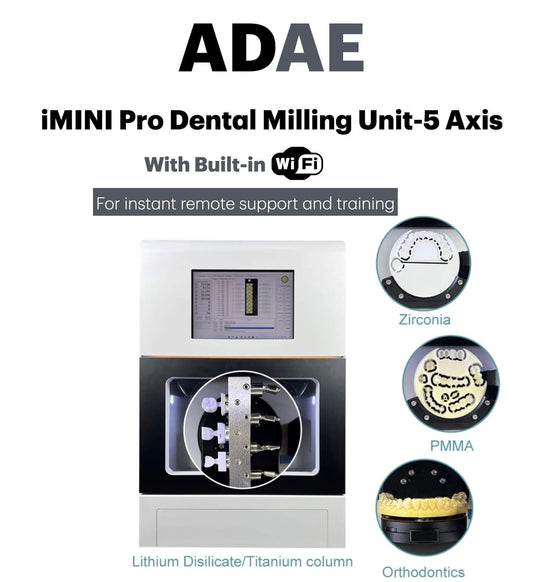

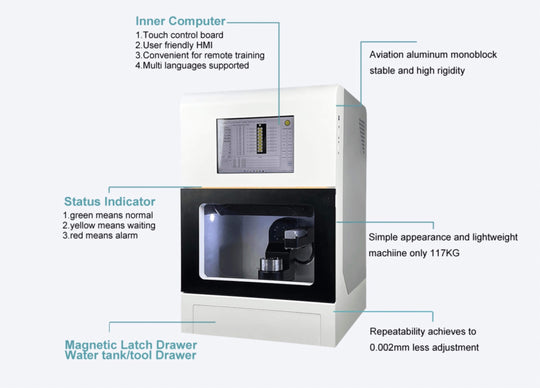

- Chairside dental milling machines

- Intraoral scanners

- Inatraoral scanner ADAE Trade-In Program

- 3D Face scanners

-

Sterilization and Cleaning Equipment

-

Dental ultrasonic scalers and air polishers

- Dental hand pieces and accessories

- X-Ray sensors

- X-ray machines

- Dental electric motors

- Dental saving packages

- Intra-oral cameras

- Build your dental clinic from scratch

- Silent Air compressors (Oil-Free)

- Dental implant products

- Dental suction units

-

Teeth whitening machines and kits

- Dental materials

- Dental laser machines

- Professional dental microscope

- Dental amalgamators

- Dental curing lights

- Orthodontic products

- Dental instruments

- Dental stools

- 3D Dental printers

- CAD Design Softwares

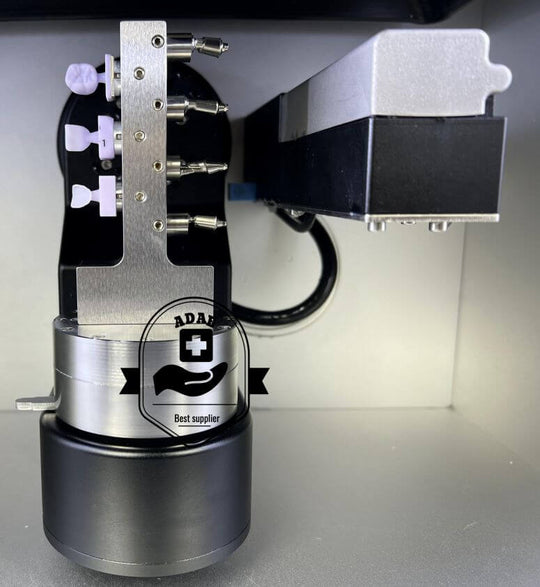

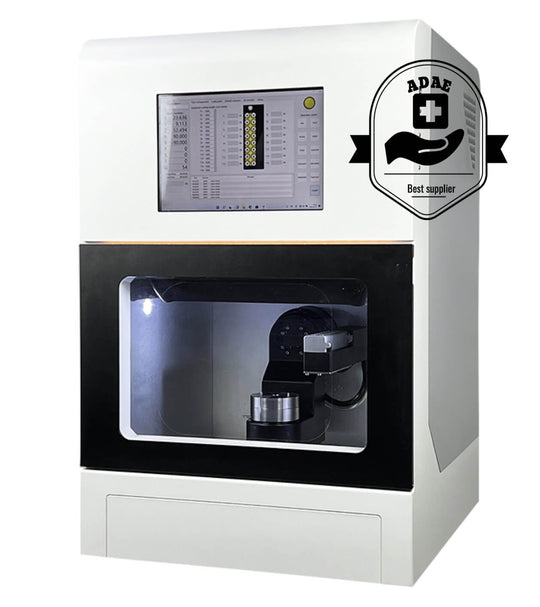

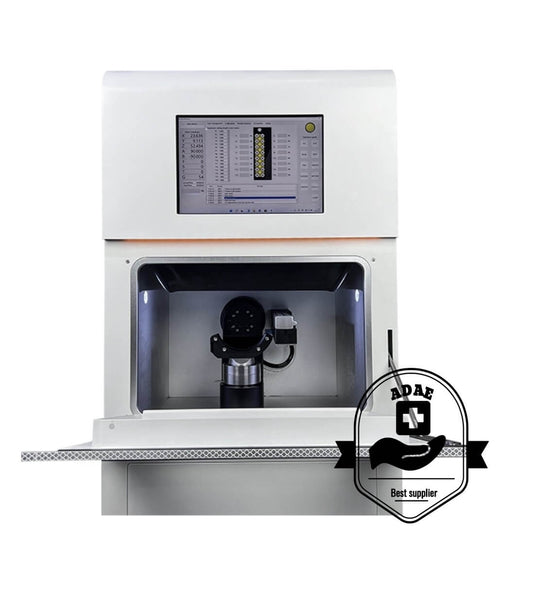

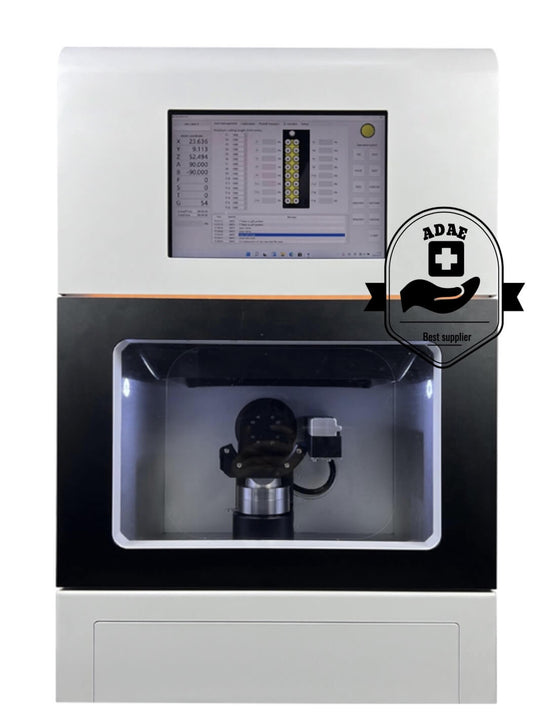

- Dental Milling machines

- Dental uniform

- Dental Photography

- Dental CBCT, OPG & CEPH

- Dental furnitures for clinics and laboratories

- Build your digital dental lab from scratch

- ADAE professional mobile dental clinic

- Dental sedation system

-

For dental laboratory

- Hot Deals and Saving Bundles

-

Dental solution and chairside system

- Dental Lab Service

- Dental consumables

- Personal dental care

- Our catalogue

- Track your order

ADAE iMini Pro Dental milling unit-5 Axis (Dry and Wet Milling)