GUIDED IMPLANTOLOGY WITH FULL IN-HOUSE DIGITAL WORKFLOW

By Dr. Luigi Rubino, MD, DDS

Guided implantology is the result of the combination of clinical data, three-dimensional imaging, and CAD/CAM design of surgical guides.

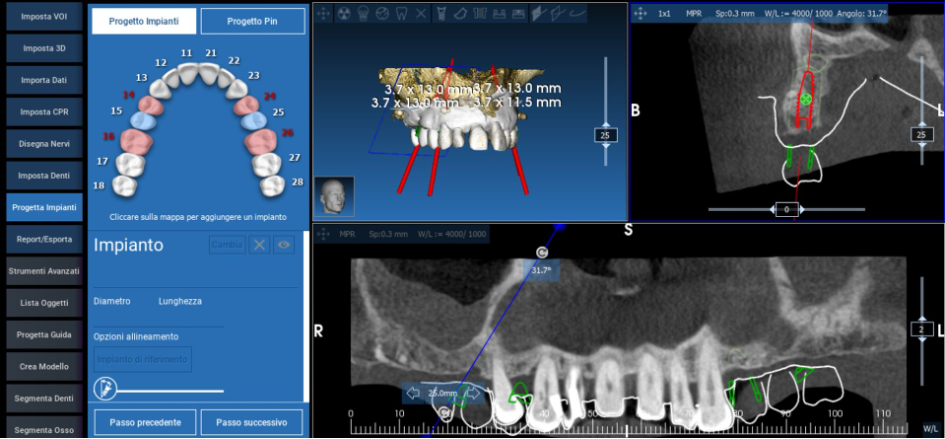

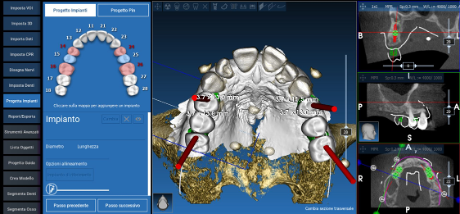

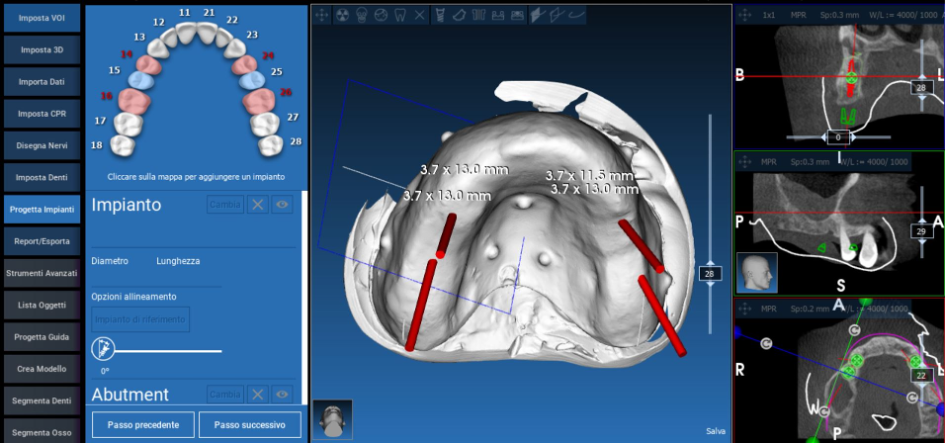

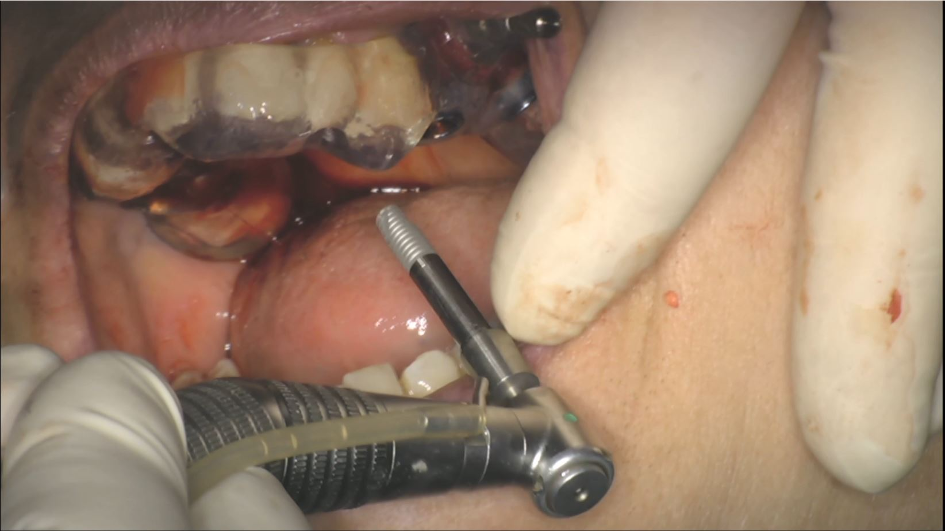

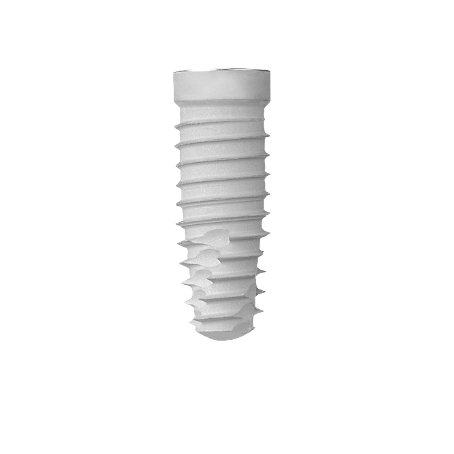

The possibility of obtaining surgical guides and 3D models from CT or CBCT images has dramatically improved the clinical precision in implant positioning with the possibility of pre-operative assessment of the dimensions of the implant, ideal depth, and angulation.

Moreover, prosthetically directed implant placement using dedicated softwares can ensure precise placement and predictable prosthetic outcomes, in order to achieve aesthetic and functional success of the restoration.

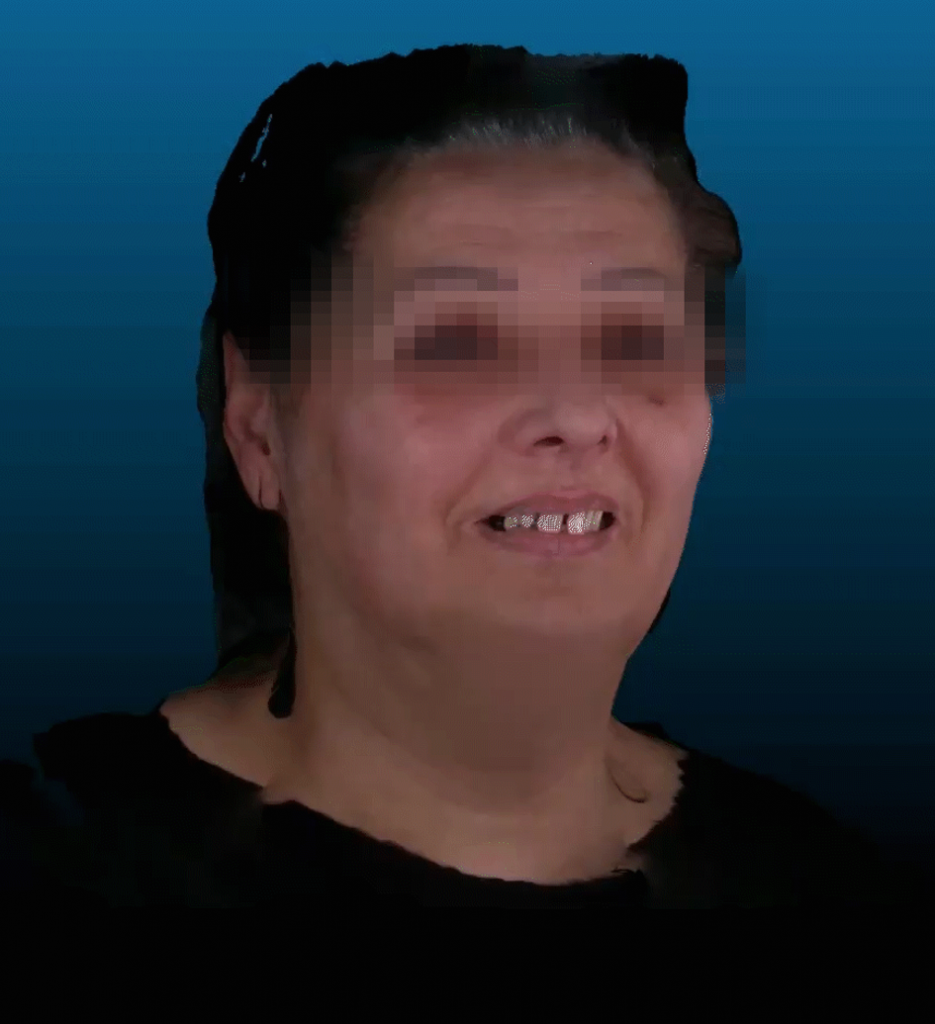

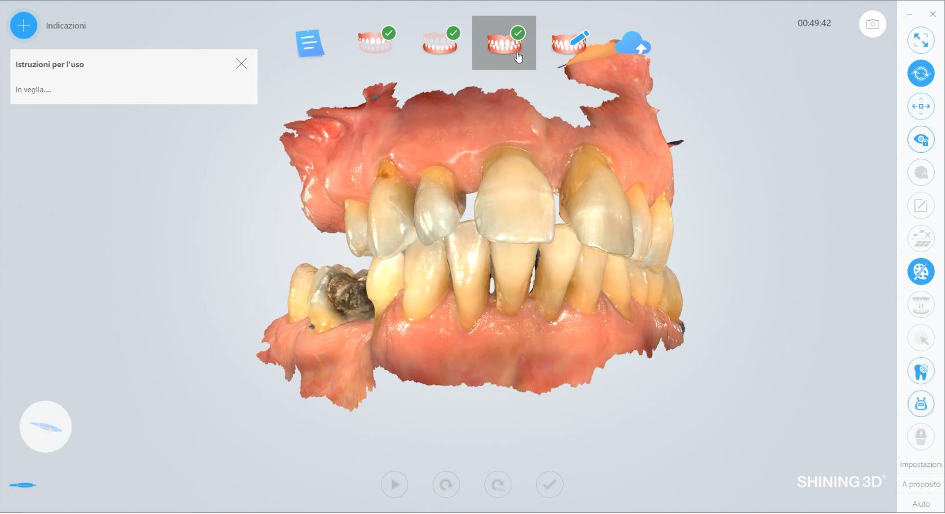

In this clinical case, CAD / CAM technologies were used to plan computer-assisted implantology and to produce the related surgical guides and customized prosthetic models in-house.

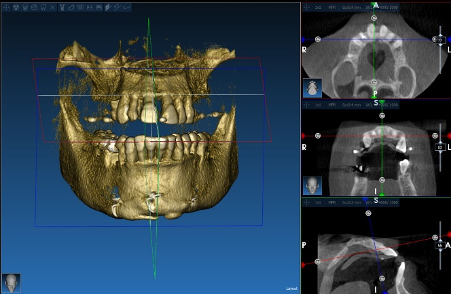

A limit found in this known technique derives from the need of the CAD or 3D imaging is to represent in a two-dimensional environment, such as for example the aforementioned display, objects which in real space occupy a space in three dimensions; a form of improvement is obtained by working on several planes, commonly orthogonal to each other, by means of multiple views possibly side by side of said objects;

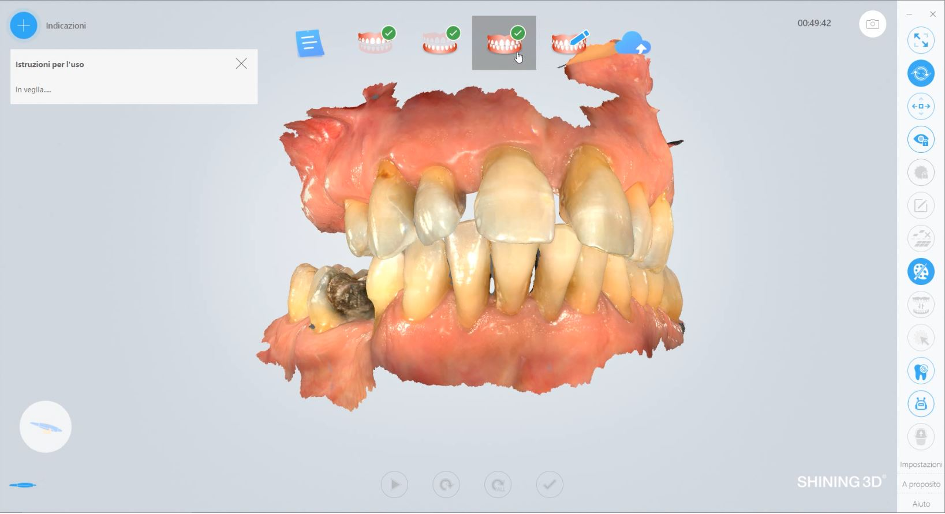

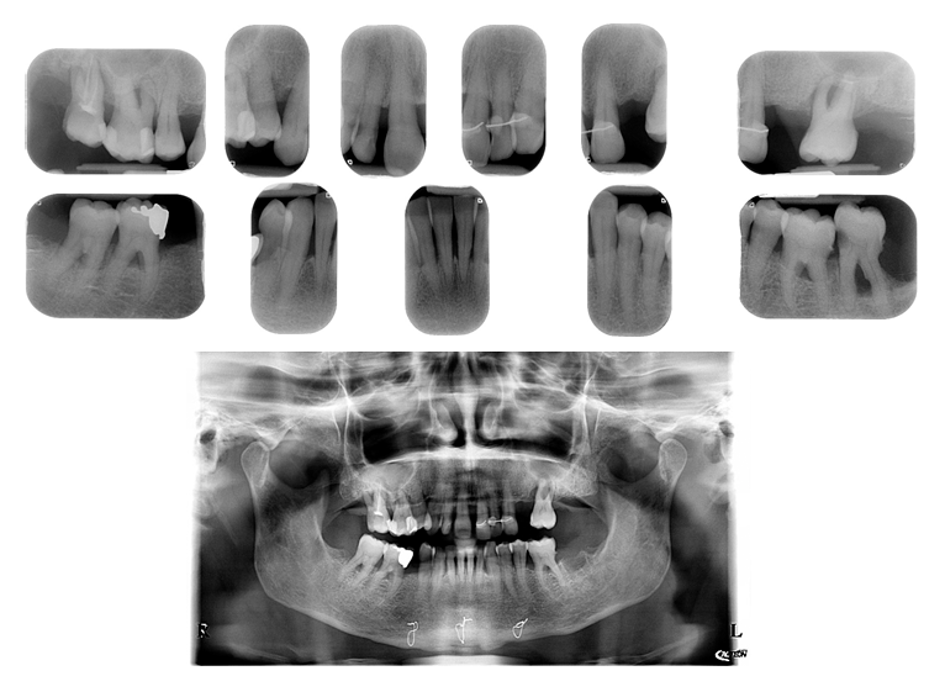

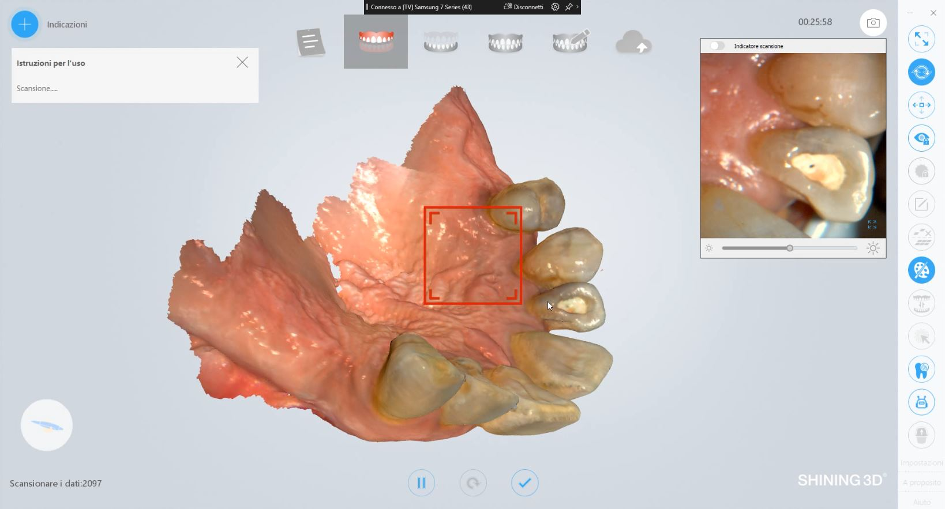

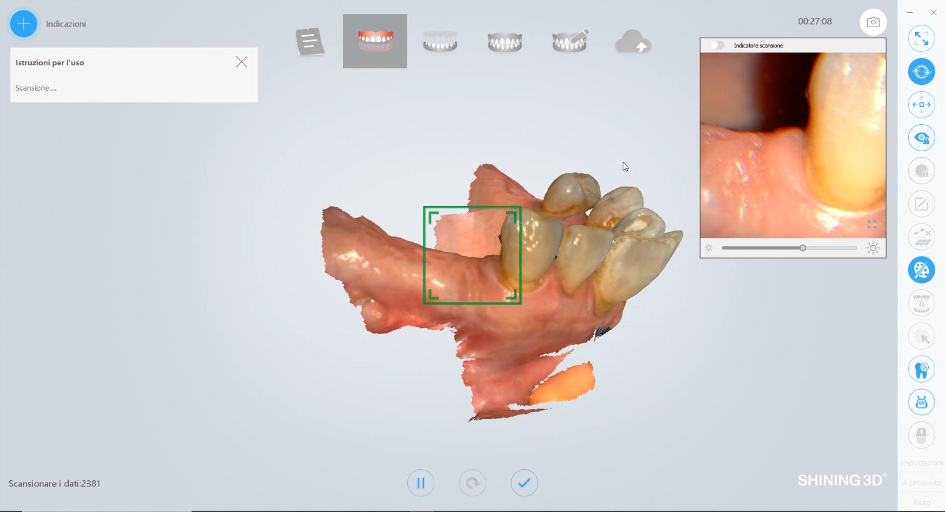

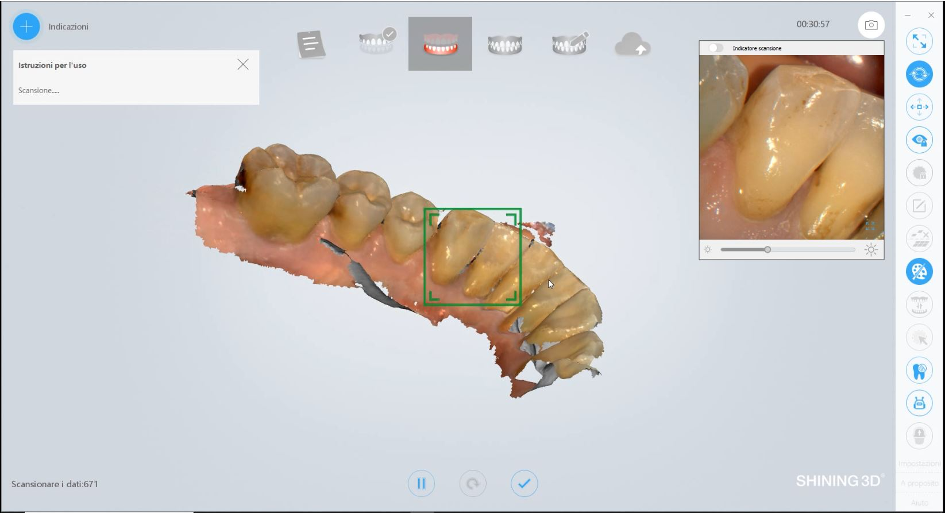

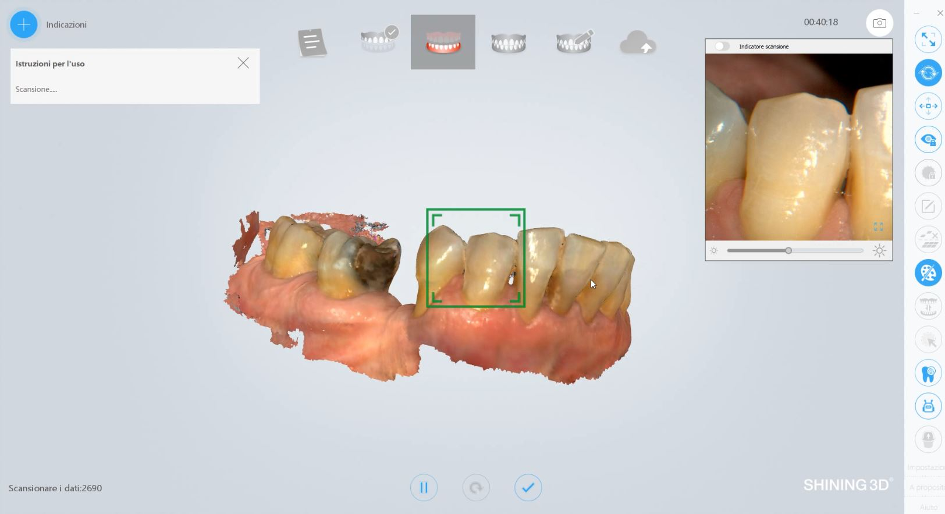

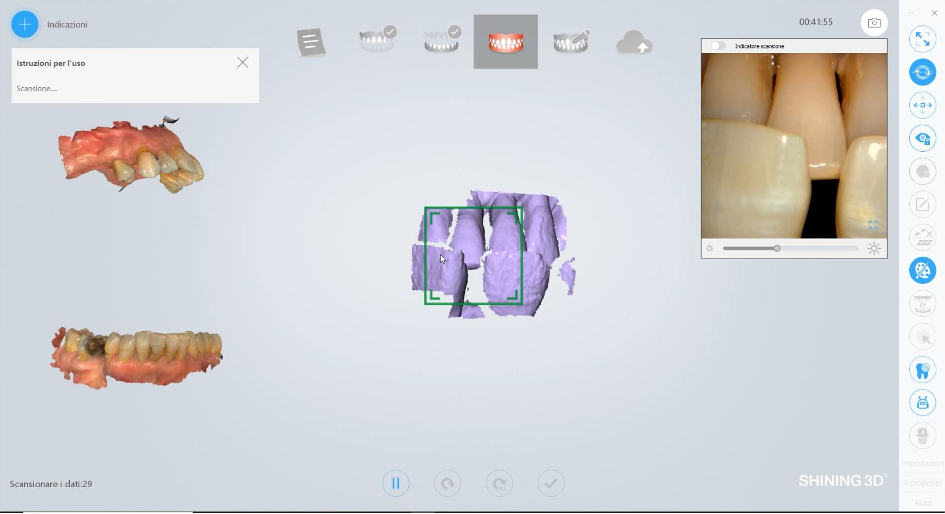

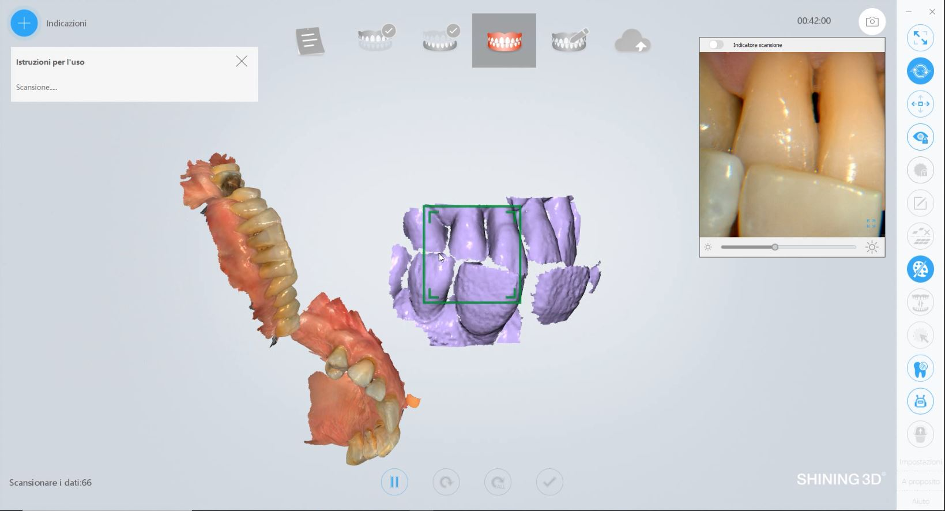

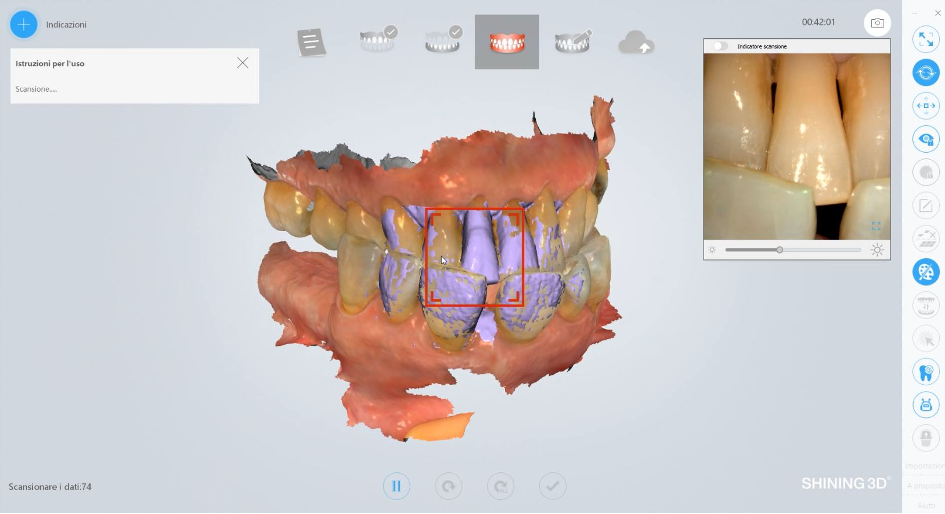

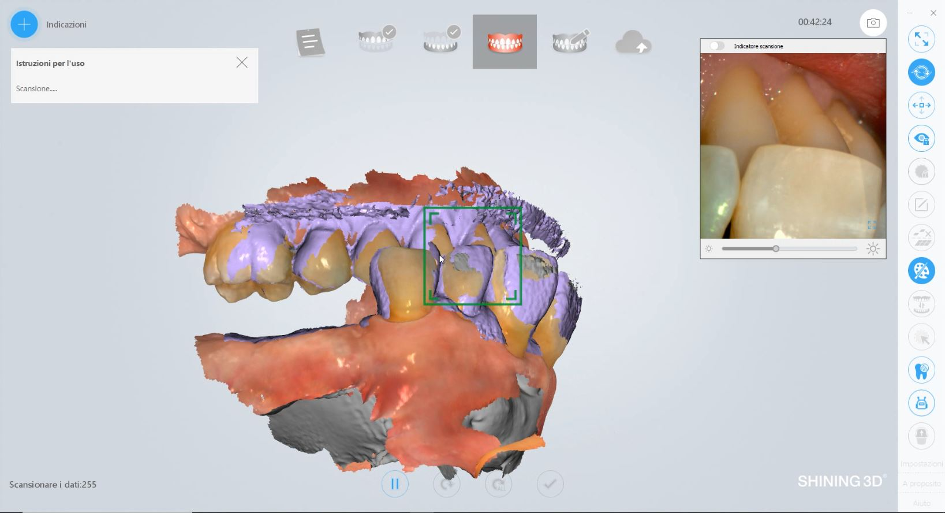

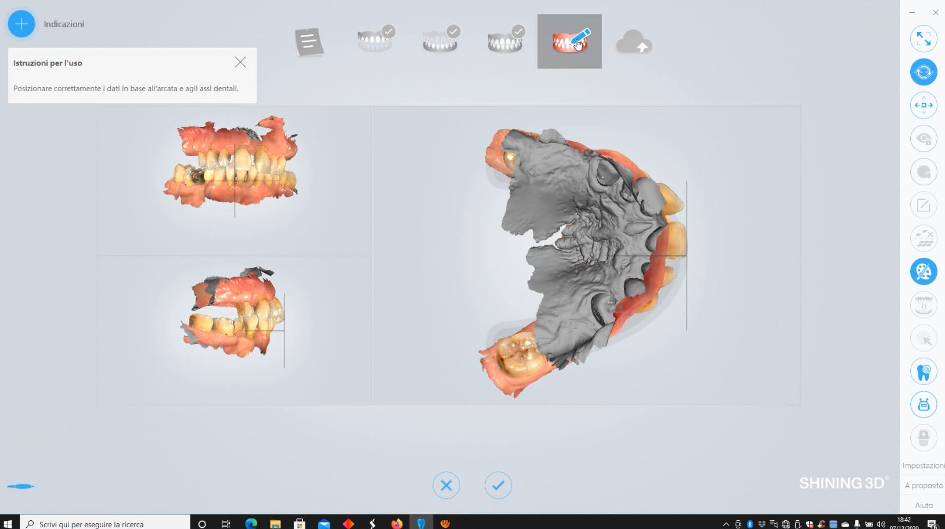

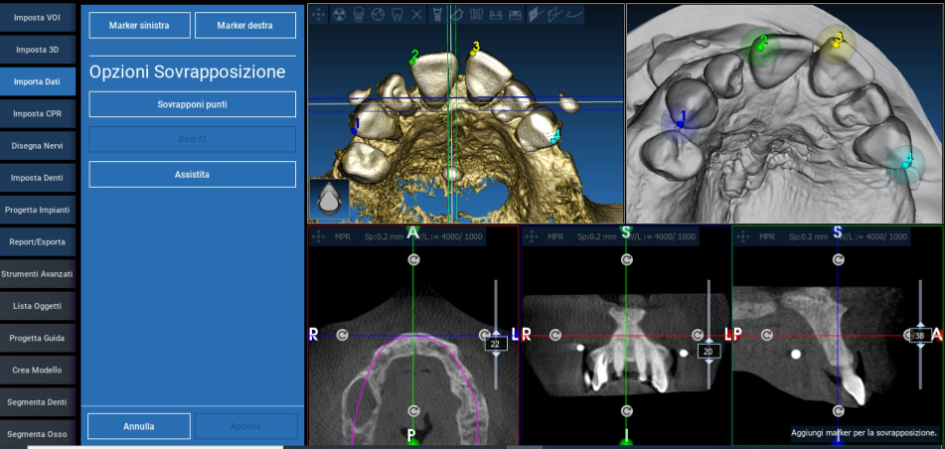

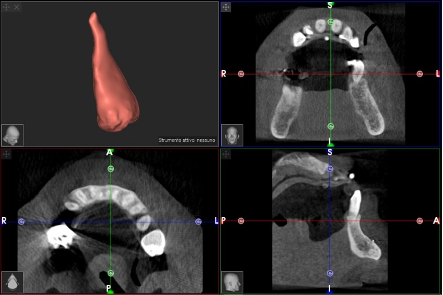

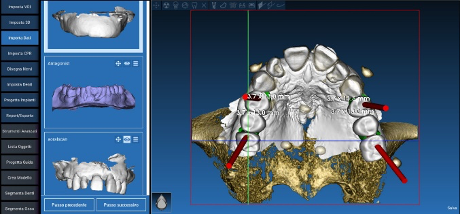

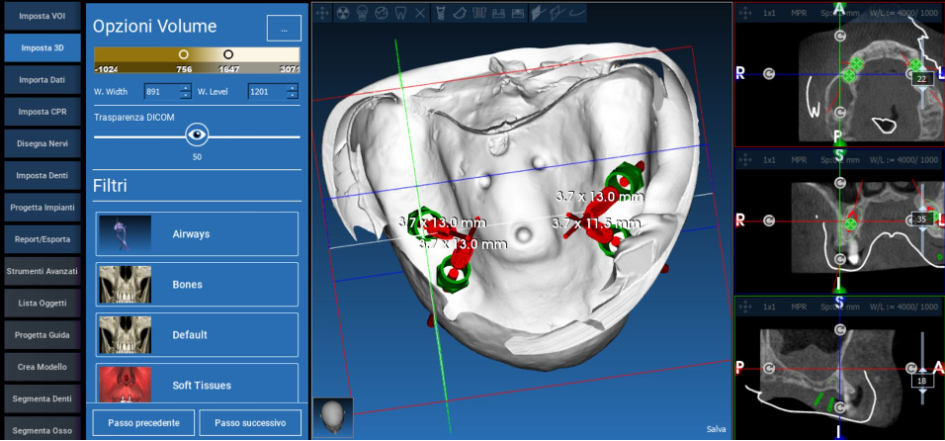

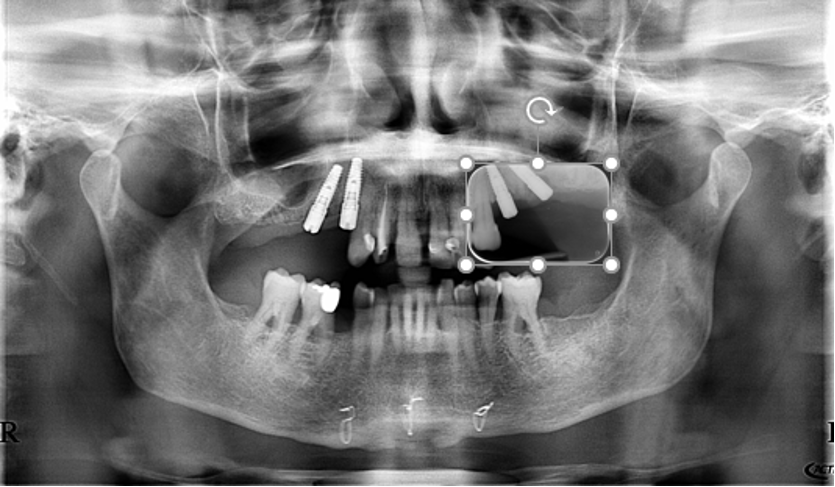

Matching STL file with DICOM file

The software can show axial, coronal, sagittal, cross sections as well as panorex and 3D reconstructions (rendering), and allow to obtain the superposition of the DICOM data with the STL files, obtained through optical scans , intra or extra oral. These software allow the selection of the most suitable sites, the shape and length of each implant, and allow to predict the need and quantity of a possible bone graft.

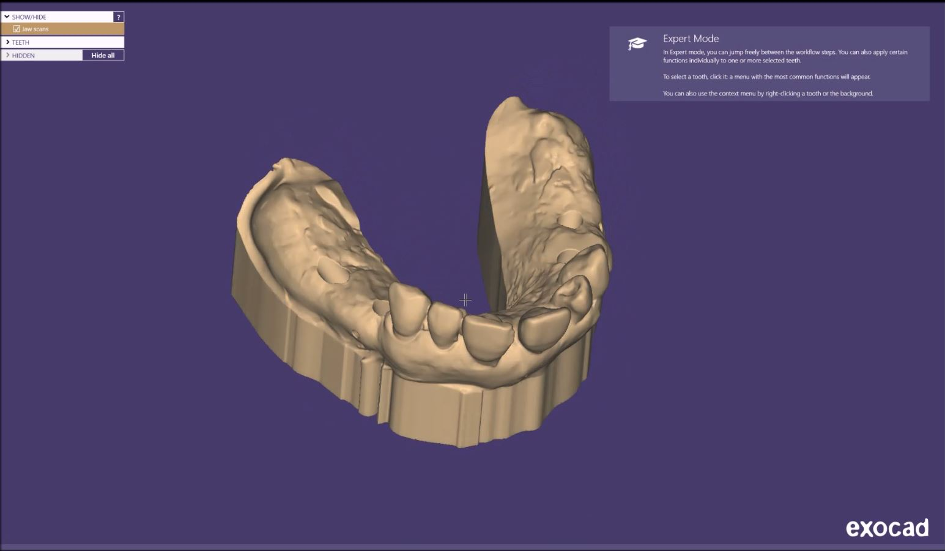

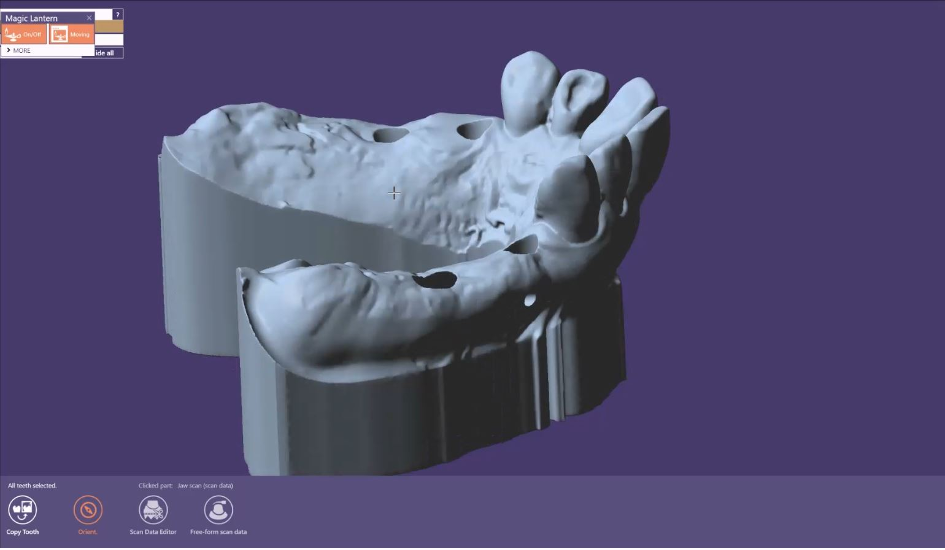

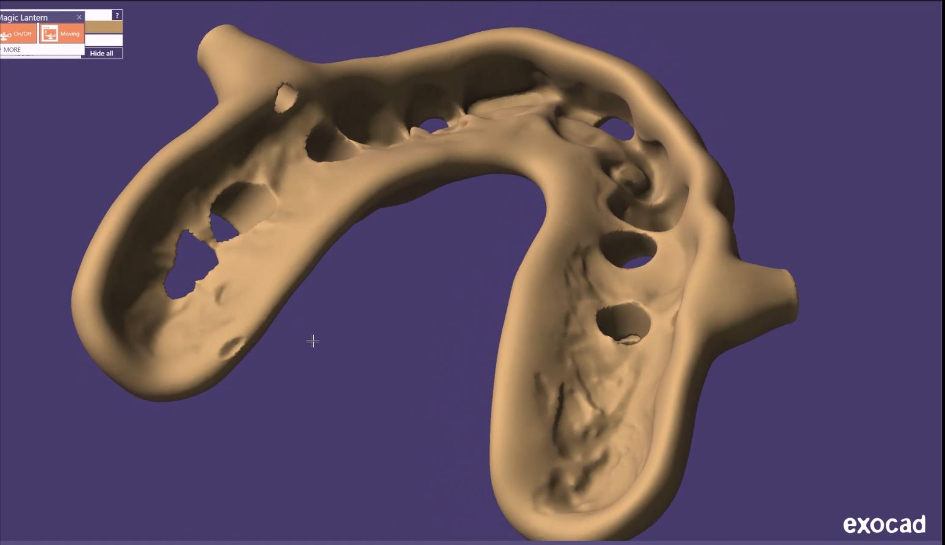

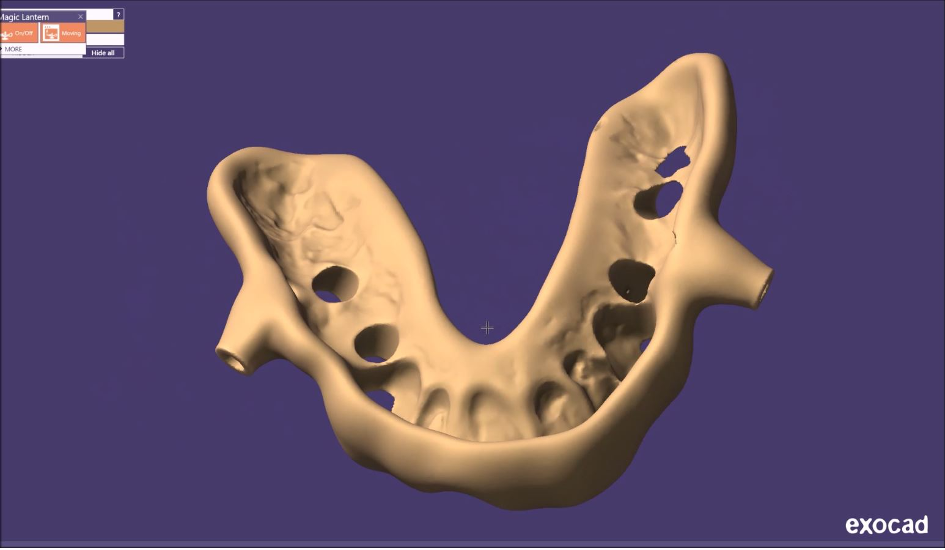

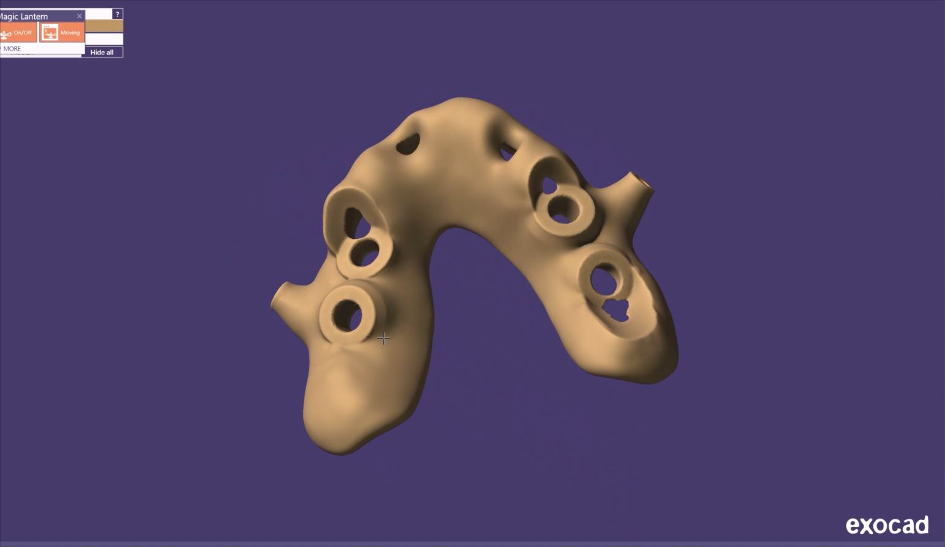

CAD design

Multiple skills are contained and made available within the technology commonly recognized with the acronym ‘CAD’, Computer Aided Design, which generally identifies a set of IT tools to support the Design activities.

This technology which has traditionally played a decisive role in mechanical, electronic or architectural engineering today involves many branches of medicine in various application forms that can range from diagnostics, to surgical simulation up to the creation of custom made prostheses or surgical devices.

Specific software technologies are used for this purpose, proposing a workspace in which digital models are created computerically and / or imported from a real model.

In the first case the digital models are already born in numerical format as they are created by special software capable of drawing one or more entities, in the second they are generated by direct acquisition of a model thanks to the use of special capture devices, such as a simple camera digital (Photogrammetry), a 3D scanner up to a common 3D medical device, such as Computerized Tomography, CBCT or MRI.

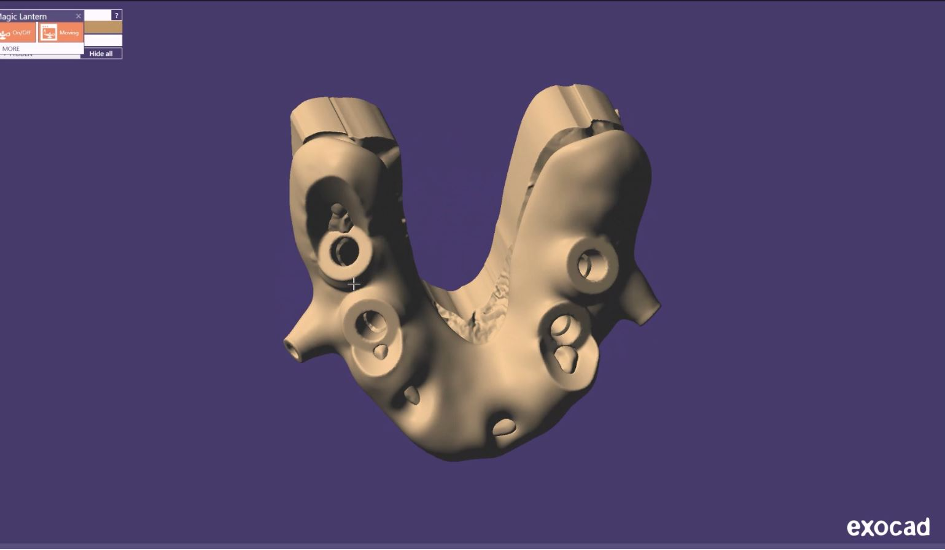

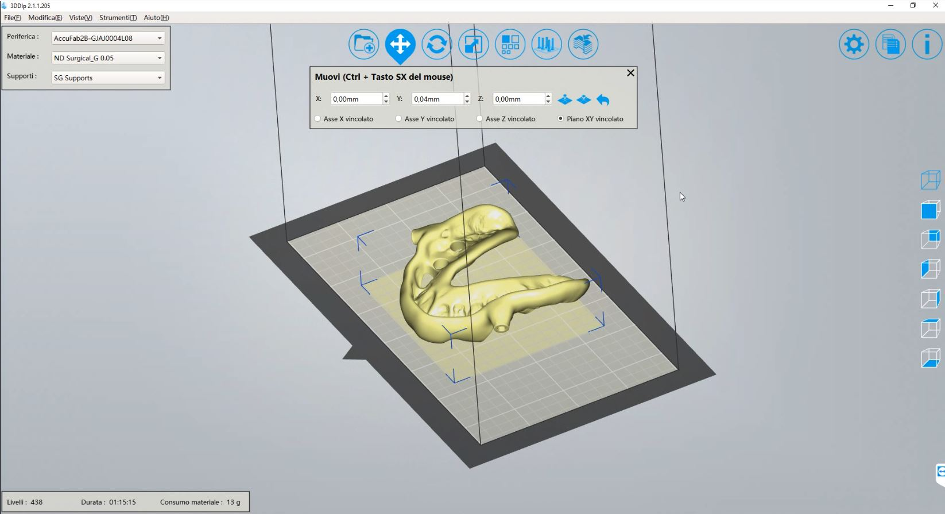

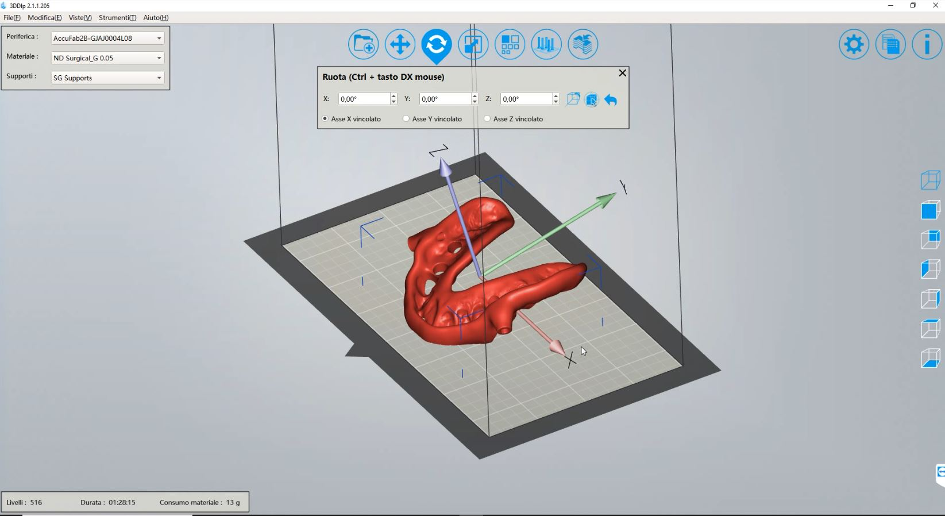

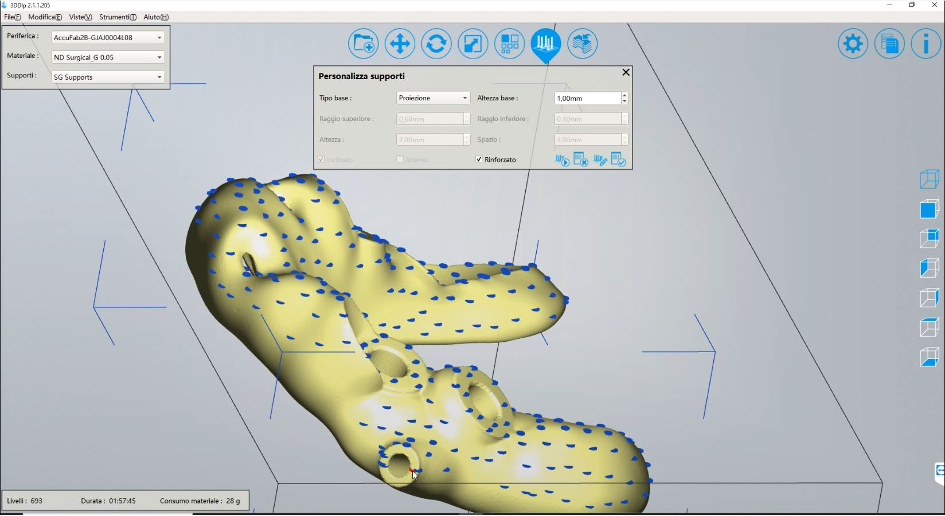

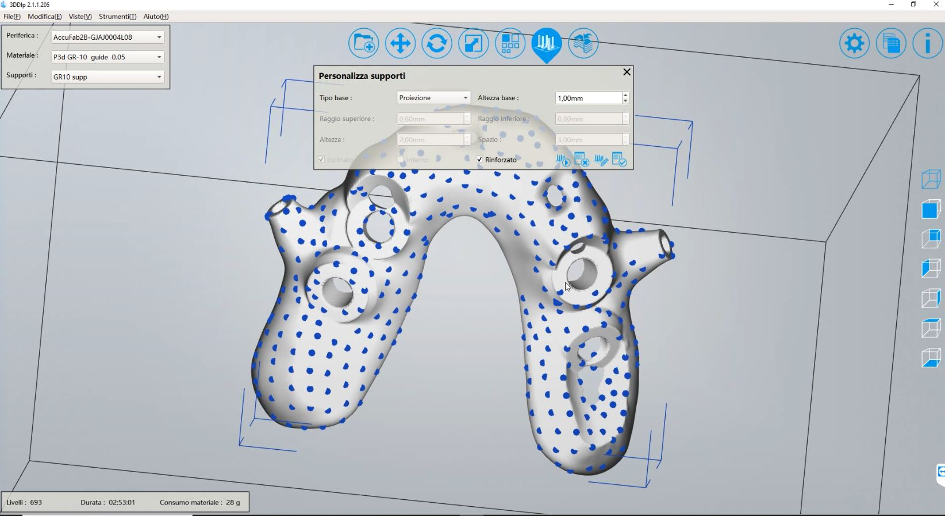

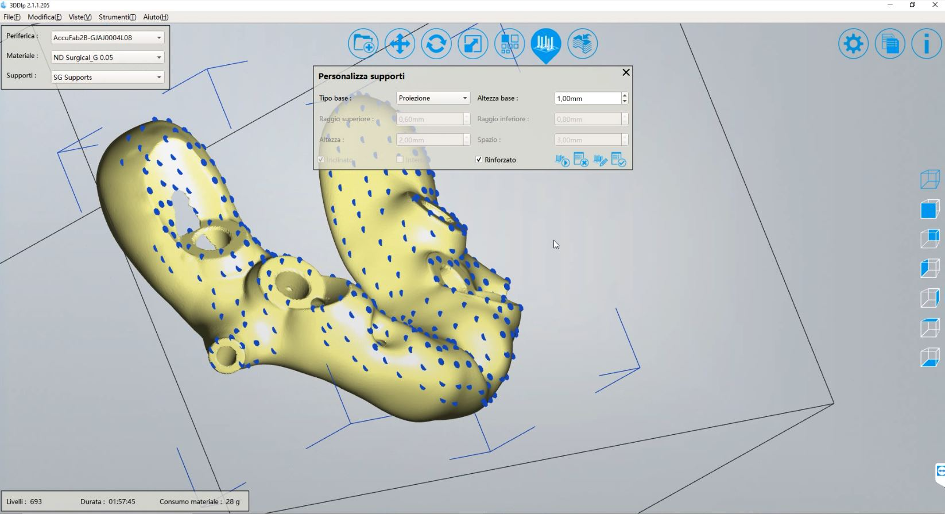

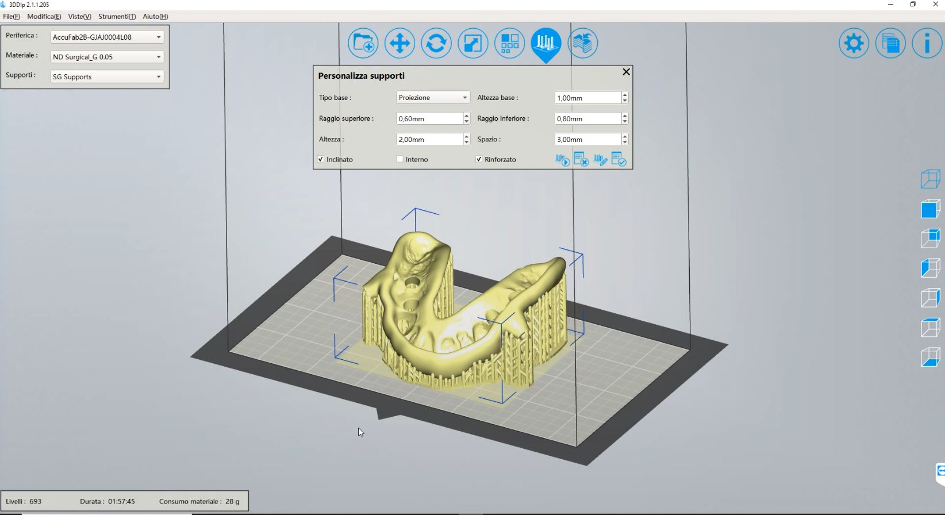

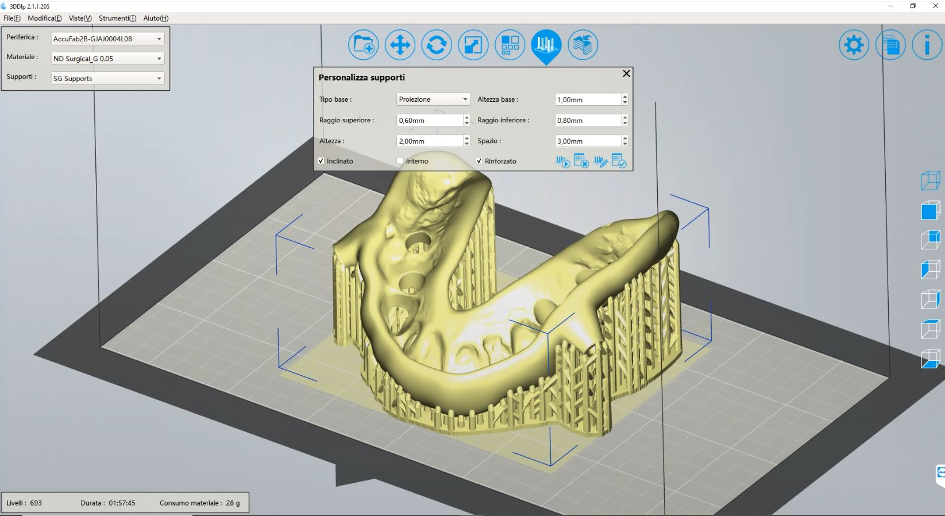

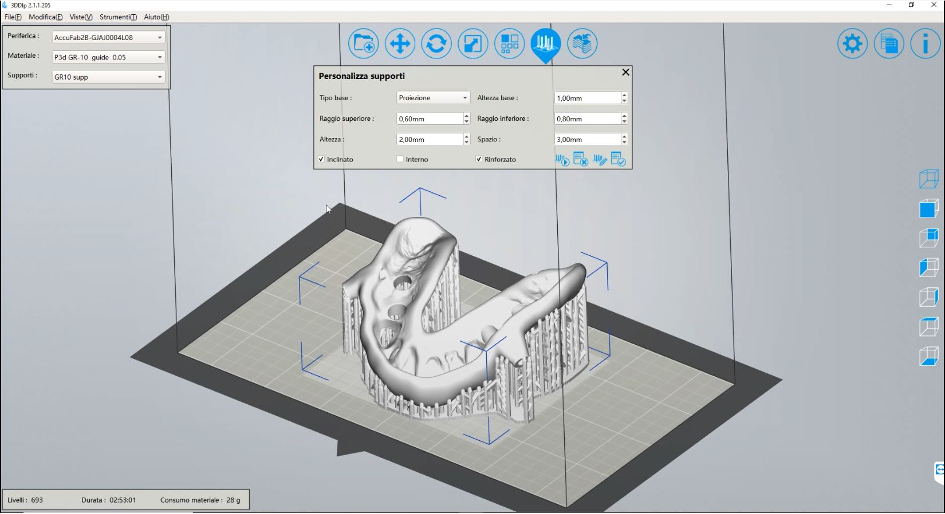

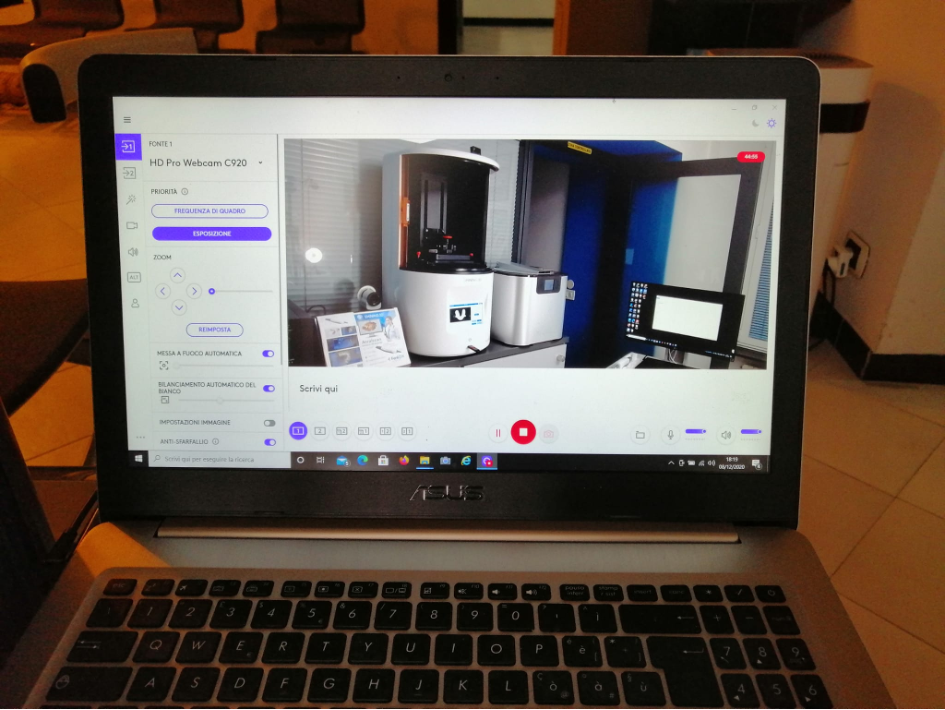

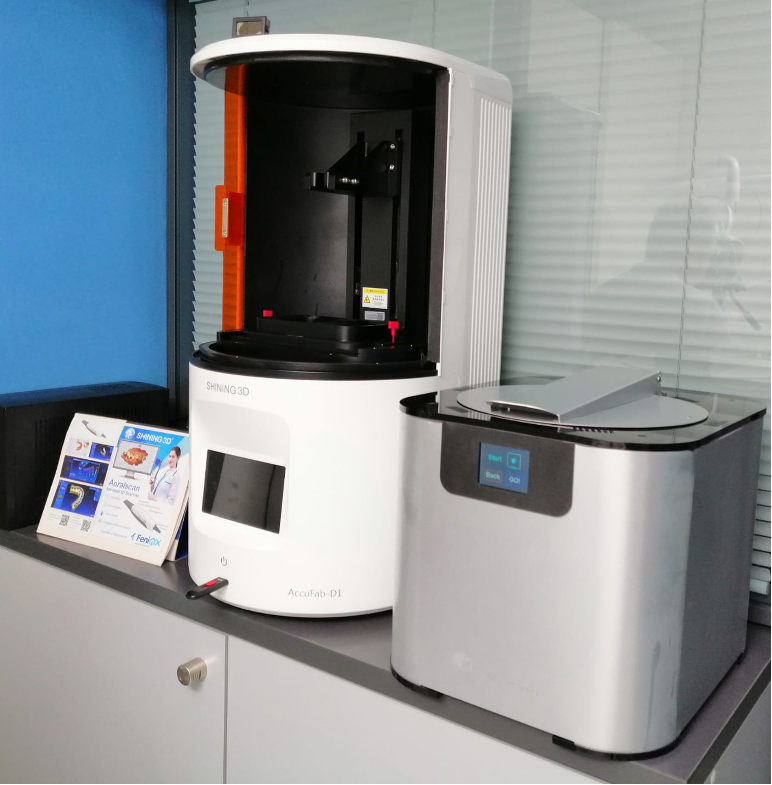

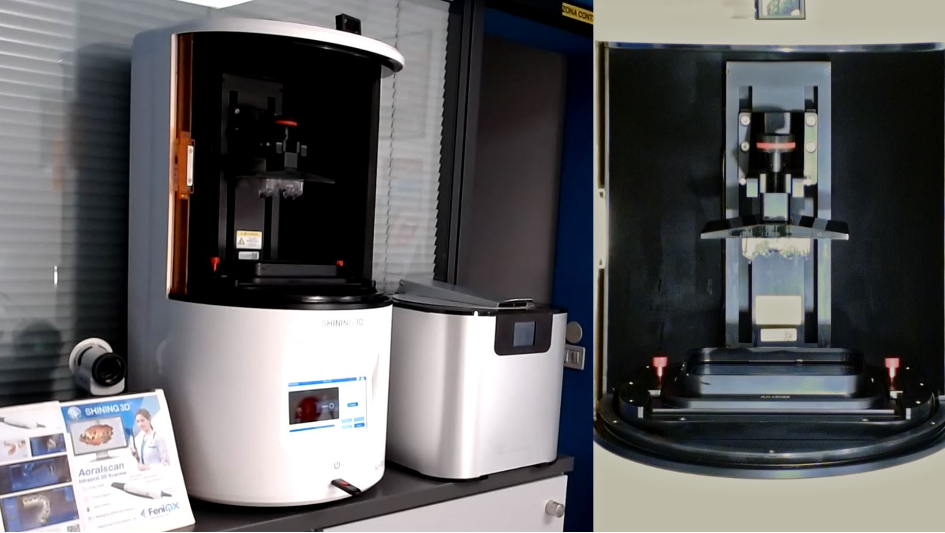

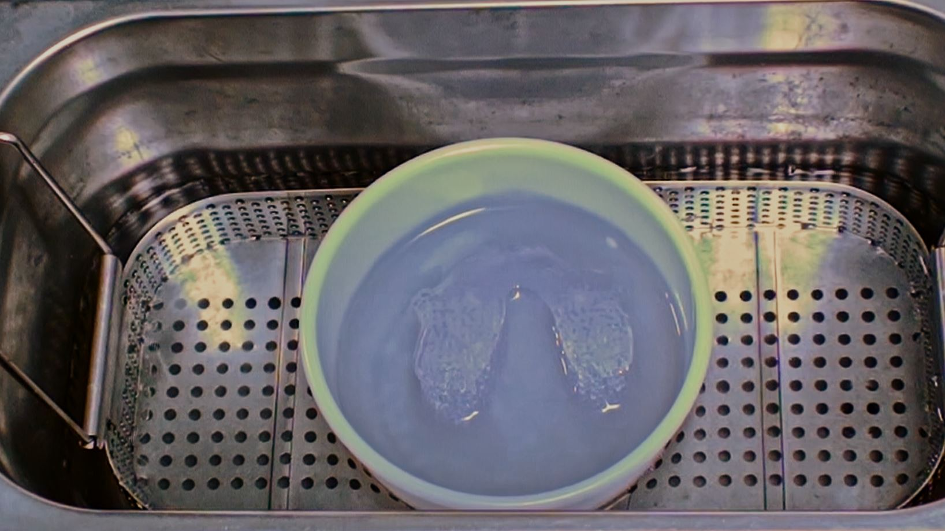

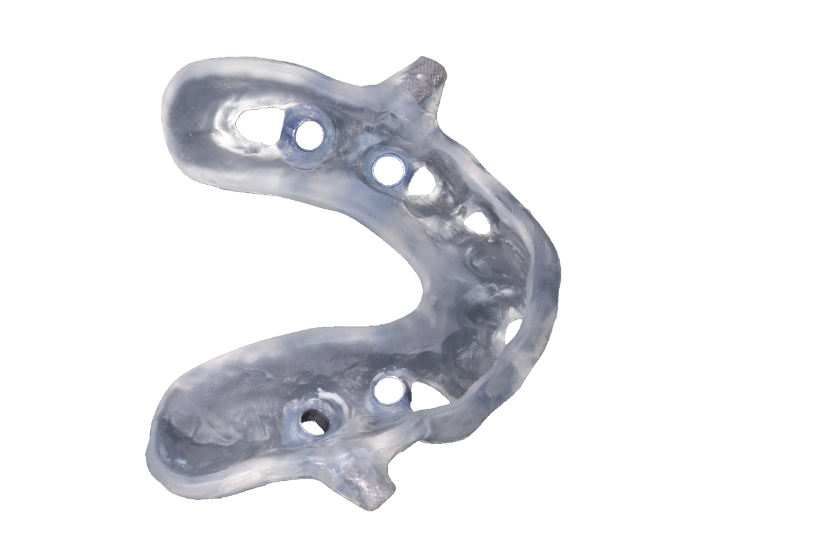

3D printing with AccuFab

The surgical template is a completely limiting guide directs the drilling process and the subsequent implant positioning offering a significant advantage to the surgeon by improving precision and minimizing complications such as mandibular nerve damage, sinus perforation, fenestrations, and dehiscences

Leave a comment