PERMANENT CROWN ON POST AND CORE_CREAMED

In recent decades, the world of Dentistry and Dental Technology is undergoing a change in the dental protocol, from analog to digital.

This means that the dental prosthesis – once realized by the artisan – is now developed virtually, by clicking a mouse and through scanning. In addition to the analog-to-digital conversion, in a few years now the dental field is at the dawn of a new productive (r)evolution: the 3D printing one, which is rapidly emerging, by offering a variety of solutions, new materials and the possibility to create dental prosthesis more quickly and efficiently, reducing waste.

For instance, most of the dental laboratories would surely realize a permanent crown on a natural crown stump from zircon, by removing the material from disks. On the contrary, in the case below we show the creation of a permanent crown on metal post and core through the additive manufacturing and with an almost exclusively digital workflow.

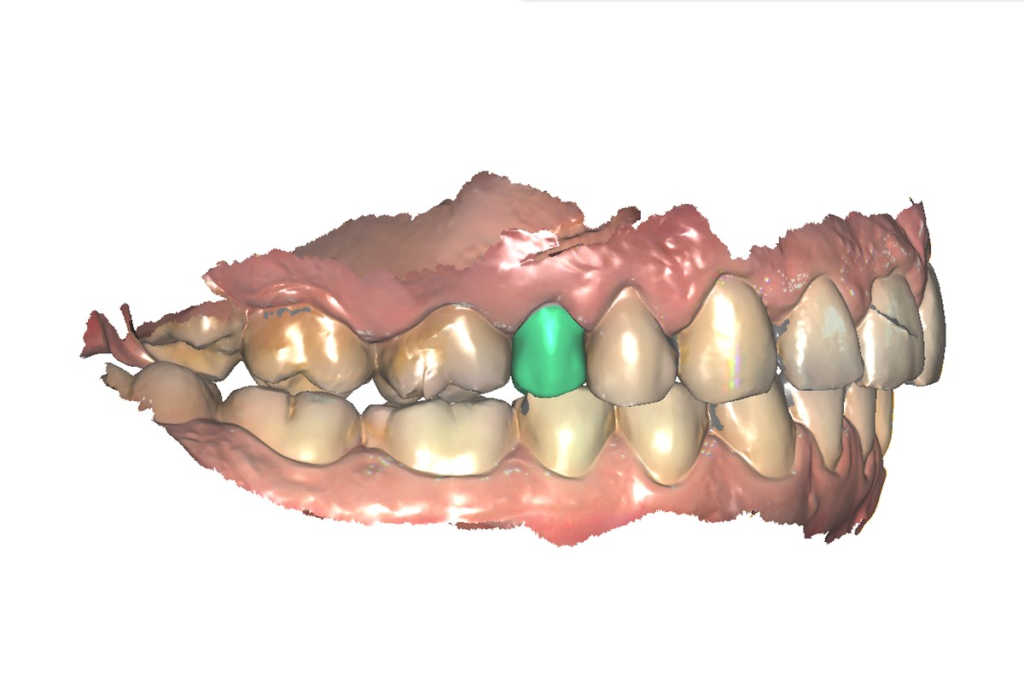

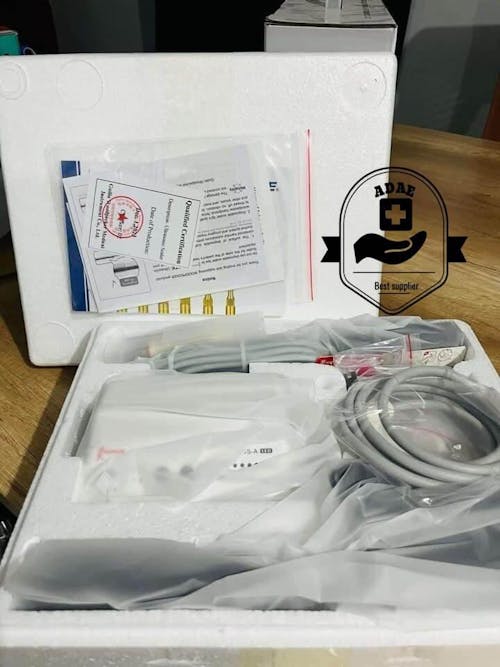

The dental record has been digitally identified with the Aoralscan by Shining3D, which made this procedure easier, thanks to its “metal tooth scan” tool. This modality modifies the acquisition settings allowing the scanning of metal elements as easily as natural teeth, without the aid of powders or mattifying.

The intra-oral impression, besides its ease of execution, provides the possibility to reduce the time spent on the dental chair with the consequent maximum comfort for the patient. The intra-oral record also – and above all – offers that immediacy of communication with the laboratory which can now bypass or postpone the steps involved in realizing the model, directly approaching the modelling and the fine-tuning of the dental prosthesis.

Thus, it becomes easy for the laboratory to optimize production and delivery time, improving the whole team efficiency. In the study case concerned, the crown has been modelled through Exocad and then printed with the hybrid micro-filled resin BEGO VarseoSmile Crown Plus A1 with the Shining3D Accufab-D1.

Thanks to the mechanical properties of this BEGO resin, it is possible to obtain very durable tooth crowns that enhance the absorption of masticatory loads and with a long-lasting degree of wear, not being abrasive for the opponent teeth.

As regards the aesthetics, the opacity degree of BEGO VarseoSmile Crown Plus contributes to conceal – even with relatively low thicknesses – the reduction in the value caused by the metal post and core crown or, possibly, colour shifts arising from dyschromic or necrotic stumps.

Thanks to this protocol, the workflow for the realization is reduced to a few hours, needed to print, finish and mark out the crown.

Accufab-D1 extreme accuracy has also made it possible to obtain high precision concerning the finish line, verified through the 3D printed models with the KeyModel Ultra Light Grey resin. This material, indeed, is ideal even in terms of aesthetics, given its neutral colour which does not affect the prosthetic tooth shades in the process of characterization of the printed model.

The versatility of the definitive material allows both the exterior painting and the layering of enamel parts, so as to lend to the crown greater three-dimensionality and naturalness. In the present case, analysing the pic colours, we opted for the superficial coloration as finishing protocol. Moreover, we worked a lot on care of the shape and texture to find the best integration with the adjacent teeth.

And finally, the crown has been sandblasted internally – in order to increase the adhesion – and cemented by means of light-curing dual cure adhesive cement.

We can notice a perfect chromatic integration from the photos showing the crown check two weeks after the cementation.

At the conclusion of the case study, we can assert that the essential synergy between the AoralScan and the Accufab printing system by Shining3D enables us to achieve highly accurate results, during both the data acquisition stage and the realization of permanent teeth, even in particular cases, like the one shown.

The difficulties encountered with this case consisted exactly in dealing with a metal post and core, which could have caused some acquisition problems during the intraoral scan, undermining the reliability of a completely digital protocol concerning the realization of the crown.

The implementation of innovative and highly performant materials, such as the Bego VarseoSmile Crown, let us obtain a sure resistance in the short run (time elapsed between the cementation and the first check) and a good chromatic integration.

Certainly, we can notice a light greyish shade in correspondence of the cervical part, due to the presence of the metal post and core. Nevertheless, we wanted to push further specifically to test the limits of this procedure (if there were). As regards vital stumps, we are sure that the material features would be highlighted from an aesthetical point of view, by perfectly integrating from the finish line to the incisal edge and getting the colour from the stump for a more natural integration.

We truly thank the Laboratorio Odontotecnico di Michele Di Bisceglie for their cooperation and support to the development of this study case.

Leave a comment